ENVIRONMENTAL RESPONSIBILITY

We diligently select and procure materials that are healthy for individuals and the planet and we manage resources, such as energy, wisely.

Manufacturing & Operations

- Low levels of emissions are created in transporting supplies to Swiftspace’s facilities as major suppliers are located within a 50-mile radius

- Swiftspace uses LED lighting in both the assembly floor and office space. Motion sensor lighting is also used in low traffic areas to preserve energy.

- Swiftspace carefully separates waste to responsibly recycle materials. Swiftspace also reuses what they can in floor tooling and packaging.

- The packaging medium used is 100% recycled material of 100% post-consumer waste

- All aluminum and panel parts are shipped from suppliers on reusable skids

- Products ship on reusable skids with minimal packaging made from recycled cardboard

- Station covers are made from excess commercial grade furniture vinyl diverted from landfill sites

- All Swiftspace furniture is made and tested to meet BIFMA testing requirements.

Transportation

Product ships in approximately 15% of space of a standard workstation and has about 40-50% less weight, both of which translate into a reduced carbon footprint

The ability to fold-up when not in use will result in reduced space requirements which will translate into a reduced corporate carbon footprint

The mobility of the product will allow it to easily handle relocation/reconfiguration without having product end up in the landfill site

Stations arrive fully assembled so installers are required for set-up, saving fuel costs of installers traveling to site

Installers are not required for reconfiguration and movement of product for subsequent movement of stations

Mindful Materials

1. PET Acoustic Panels

Are 100% recyclable, and contain 50% recycled PET.

2. Steel

Includes recycled content whenever possible and uses a powder coat finish to minimize paint waste.

3. Particleboard & MDF

CARB compliant, produced using no added urea-formaldehyde resin, made from 100% recycled and/or recovered pre-consumer wood material.

4. Laminate Adhesive

Solvent free, water based PVA which meets Greenguard Indoor Air Quality Standards for Low Emitting Products.

5. Hollow Core (OSB)

Engineered to maximize the utilization of standard size sheets of material.

6. Fabric

Offer fabrics that include sustainable characteristics such as recycled content, GreenGuard certified, and free of PFAS and phthalates.

- All panel dimensions have been sized to completely utilize 4 x 8 sheets of material

- Recycled materials have been used whenever possible

In Office Use

All stations are certified MAS Green Standard for low VOC emissions for a healthy indoor office air environment.

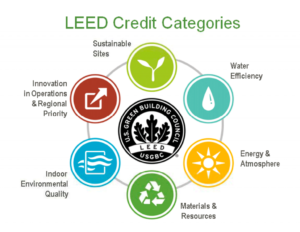

Swiftspace stations can be used to contribute towards LEED credits

Swiftspace stations consume no or minimal energy on average as the desks that do include height adjustability run on 0.1W when not in use

End of Life

- Easy to field-install new panels, work surfaces, casters which will increase the life cycle of the product

- Swiftspace stations are made to last with all including a 5 year warranty. Stations like Ensemble can be continuously reused for different purposes as offices’ needs change. Swiftspace can also replace worn or damaged parts to lengthen station lifetimes further.

- Swiftspace stations can be taken apart for proper recycling and waste management

Learn more about Swiftspace sustainability: